In a 12-month period of time that has had just about every imaginable issue come up for the world, and the auto industry, the one that people were perhaps least prepared for is the ongoing computer chip shortage. Although this has hit the entire auto industry, today, I’m going to take a look, primarily just at the Ford Motor Company and how they’re handling this situation. To be honest, they’re all pretty much dealing with it in the same way, so looking at Ford compared to GM or Toyota is a fairly good representation of the industry.

Let me go ahead and spoil the ending for you: it’s not looking good for Ford or their customers. So if you’re a fan of Ford and their vehicles, then you’re in for a bit of a rough time. Expect prices on models to go up, especially ones that rely on numerous computer systems like the all-new Ford Bronco and the Mustang Mach-E all-electric SUV. Prices are going up, supply will continue to be limited, and it’s going to be a bumpy ride for longer than Ford would like you to believe.

What is this Semiconductor Shortage?

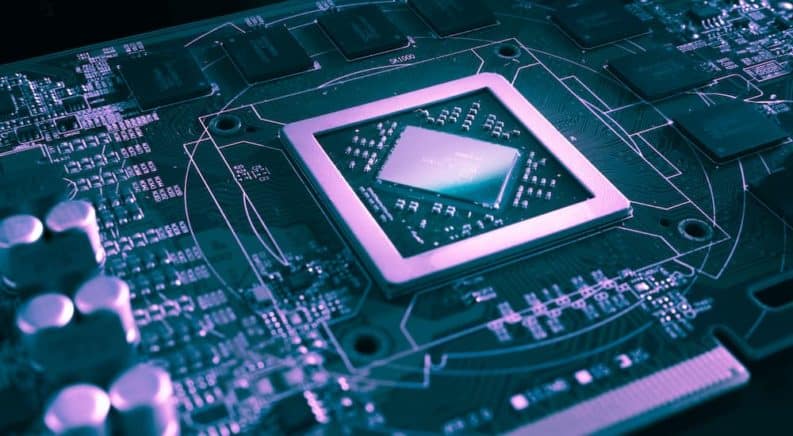

First things first, let’s step back a moment to get the big picture view of what’s going on with this whole “shortage” situation. The first thing you need to understand is that just about everything being manufactured these days uses some sort of computer technology. Whether you’re looking at an obvious thing like a computer, smartphone, or car, or something like a television, video game system, or even a digital watch – there are computers in everything.

And all of these computers rely on semiconductor chips to actually do what they do. These aren’t optional features or only used for the most powerful systems. There are no modern computers, or essentially any digital electronic device or product, without semiconductor chips in them. They are absolutely necessary; extremely complex systems can use many of these chips, all working together as part of a larger computer.

Last year, the semiconductor industry was hit just like pretty much every other manufacturer when COVID-19 shut down plants and slowed production. Eventually, plants opened back up and started making chips again, but the damage was done. There’s now a massive backlog of requests for these chips from other manufacturers that use them in building their own electronic devices, which would’ve caused a minor shortage even in optimal conditions.

In addition to this initial shortage, last year was a huge one in terms of the demand that manufacturers had for chips. Sony and Microsoft both launched brand-new video game consoles, while Nintendo continued to have huge success with its latest console. New phones were in development, such as the latest iPhone from Apple, all of which need these chips. Plus, more computer systems are being used in cars, especially electric cars that require more computerization for optimal performance and new features like semi-autonomous driving. So there was a tremendous surge in demand for these chips; at the same time, there was a drop in supply due to COVID-19. This has created a disastrous shortage.

Who Has Been Impacted by the Shortage?

Pretty much any manufacturer you can think of that makes products with computerized systems in them has been affected by this. The biggest ones are the companies that use the greatest number of these chips, which happens to be Apple and Samsung. Now, just to give you a sense of how huge this market is, Apple spends about $58 billion annually on semiconductor chips (yes, that number is JUST for the chips they buy), which they then use in their computers, tablets, phones, and everything else. Samsung is a strange case because they actually produce chips and use them – they sell $56 billion worth of chips to other companies each year but also require $36 billion worth of chips for their own production.

That’s the kind of money and the massive numbers of these chips that are being made and sold every year so that all of these industries can keep making electronics. By comparison, the entirety of the auto industry across the globe spends about $37 billion on chips every year – about as much as Samsung by itself. So, you can see that when it comes to demand, companies like GM and Ford don’t even come close to what Apple requires and the kind of money that Apple spends.

How Ford is Being Hit

This brings us to Ford and the situation that it’s currently in. The semiconductor shortage is hitting the entire auto industry, and Ford is a great sample case for what it’s done. So far, Ford has tried to remain optimistic and talked about minor delays and issues, but the reality is probably a lot grimmer than they’d like to let on.

In early March, Ford sent out a letter to dealerships letting them know that there would be some decrease in production and lower volume. But that this would be pretty minor overall, and that production would pretty quickly go back up. It was full of positive language about being excited for mutual growth in 2021 and incentives for retail orders, etc. But then, a few weeks later, Ford paused production on the F-150 for at least three days. The F-150!

If that doesn’t illustrate the reality of this situation, then I’m not sure what will. Yes, it was only a three-day pause, but that’s still significant. This is in addition to the fact that Ford had previously commented on continuing production and holding onto models until they could be completed – presumably when microchips were received – and then finishing them before shipping them out to dealerships. But now, we have a pause in manufacturing.

What This Means for You

To put it simply: prices are going to go up, and vehicles are going to be delayed. As a customer, those are the two main takeaways you should keep in mind with this situation. If you’re really excited about one of the brand-new models like the F-150 Raptor, Bronco, or Mustang Mach-E, then this is definitely not great news for you. These models have some of Ford’s latest technology in them, so they’re certainly going to be hit by this chip shortage.

That means it’s going to be very difficult to find these vehicles, assuming they actually meet their current launch dates. And once they do come out, it’s possible that prices on them will be higher than expected – after all, experts are suggesting this shortage could cost Ford up to $2.5 billion in profit. GM is in similar shape, looking to take an estimated $2 billion loss from this shortage. Worst of all, there’s no change to this situation on the horizon.

What’s the Future Outlook?

Manufacturing semiconductor chips takes time, and building facilities to make them can take a couple of years. So even if companies here in the US started working on no longer being reliant on overseas production right now, they’d still be looking at two years before they start producing anything. And the plants making them right now are going to require many months, perhaps even a year or two, to actually get caught up.

As chips are produced, it’s a safe bet that companies like Apple and Samsung are going to get the first crack at them since they spend so much on them. That leaves Ford even further in the lurch, and the long-term impact of this is going to be much more significant than a three-day pause in production or a few canceled shifts. Things are going to be rough for a while. With any luck, however, the result will be a surge in tech manufacturing here in the US so that we don’t rely as much on components coming from overseas.